Ranger

Ranger Combo R26FLT- RB24T Super‐Duty Truck Changer & Wheel Balancer with Drive‐Check™ Technology with Deluxe Adapter Kit & Quick Chuck

- SKU:

- 5140137 - 5140149

- UPC:

- 5140137 - 5140149

- Availability:

- FACTORY SHIPPED

- Shipping:

- Free Shipping

Description

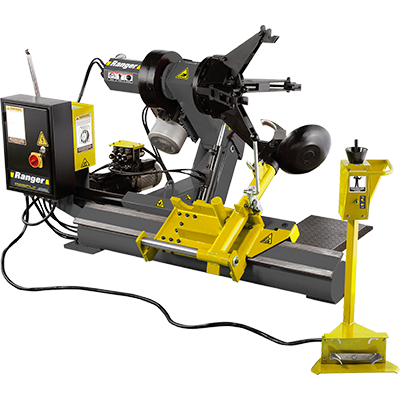

Ranger R26FLT Super Duty Truck Tire Changer

The Ranger R26FLT is a super-duty tire changer that handles the truck, bus and commercial van tires with ease. Comes with joy stick control.

R26FLT (5140137)

Heavy-Duty Truck Tire Changer / Joystick Control

The Ranger R26FLT is a heavy-duty tire changer that handles truck, bus and commercial van tires with ease. Comes with joystick control.

The Ranger R26FLT is a heavy-duty tire changer that handles truck, bus and commercial van tires with ease. Comes with joystick control.

R26FLT SPECIFICATIONS

STYLE

FEATURES

- Super-duty electric motor and hydraulic drive for superior torque and wheel holding power

- Self-centering hydraulic clamping chuck

- Heavy, tapered roller bearings and a dual direction hydraulic motor provide smooth torque

- Quick positioning and locking mount / demount arm

- Hydraulic sled carriage for positioning, bead loosening, mounting and de-mounting procedures

- Single piece frame for superior rigidity

- Hydraulically operated spreader jaws ensure secure clamping of virtually all rims and off-road style wheels

- Massive chuck spindle handles the heaviest loads

- Sturdy spindle, chuck and mount-demount head hydraulically rotates, raises, and lowers with simple operator controls

- Very gentle on over-the-road tires and tubeless tires mounted on aluminum wheels

- Simple design is easy to use

- Tire lubrication comes standard

- Funnel comes standard

- Large bead tool comes standard

- Small bead tool comes standard

- Rotary valve O-rings comes standard

- Fuses comes standard

- Wheel clamp comes standard

- Lever grease gun comes standard

THE ULTIMATE TRUCK TIRE CHANGER

The Ranger R26FLT is an incredibly fast and efficient large tire changer. Swap out tubeless truck, agricultural and off-road tires from 14" to 26" in just minutes. A portable remote control brings convenient precision to your finger tips and saves you precious time. We've thoroughly explored all aspects of truck wheel service to develop the quickest large tire changer possible, so high-volume tire shops can get the speed, capability and dependability that they demand.

Experience your shortest floor-to-floor service times ever, making your job easier and more profitable. All of our tire machines are built with forged, hardened and ground components designed to resist scoring, grooving and wear. Our engineers understand that speed, convenience and safety are your top priorities, so we've made them ours, as well. Ranger tire changers are built to allow operators to learn and use them quickly and safely, so you'll be up and running in no time.

PORTABLE CONTROL UNIT

Simple controls and versatile unit console let the operator safely monitor your tire changers from the most advantageous angle.

SELF-CENTERING HYDRAULIC CLAMPING CHUCK

Clamp from either the center bore of the wheel or the inside of the wheel. Either way, this tire changer has you covered.

SUPER-DUTY ELECTRIC HYDRAULIC MOTOR & HYDRAULIC DRIVE

This powerfully sophisticated, bi-directional hydraulic motor delivers smooth torque to the tire changer at all times.

STURDY SPINDLE, CHUCK & MOUNT / DE-MOUNT HEAD

The entire assembly gracefully rotates, raises and lowers via easy-to-learn, simple-to-use operator controls.

QUICK SETUP

The R26FLT tire changer features an exceptionally swift-positioning, locking mount/demount arm.

DESIGNED TO PERFORM AND BUILT TO LAST

Ranger tire changers can take whatever punishment your shop can throw at them. They’re easy to control and rugged enough to hold up for years of low-maintenance service. The welded steel body is just the start: this tire changer boasts aluminum-alloy air cylinders and completely sealed components, making it one of the hardiest tools you’re likely to put in your shop.

HYDRAULIC SLED CARRIAGE

Hydraulic sled carriage for positioning, bead loosening, mounting and demounting procedures.

ONE PIECE

Tire changers with single-piece frames offer superior rigidity over time.

SPREADER JAWS

Hydraulically operated spreader-type jaws ensure secure clamping of virtually all rims and off-road style wheels.

SAFE AND EASY TO USE

It’s simple: our sensible ergonomic design means easier operation for you and your technicians.

POWERFUL BEAD BREAKER

Quick set-up and a powerful stainless steel air cylinder provide plenty of tire-busting power. Combine that with our durable bead breaker blade, and you’ve got the capability to service virtually anything that rolls into your shop.

MASSIVE CHUCK SPINDLES

Huge spindle to handle the heaviest loads.

BUILT-IN STURDINESS

Sturdy spindle, chuck and mount / demount head hydraulically rotates, raises and lowers with simple operator controls.

A GENTLE TOUCH

Very gentle on over-the-road tires and tubeless tires mounted on aluminum wheels.