BendPak

BendPak 1302BA-302 Digital Automatic Exhaust Pipe Bender

- SKU:

- 5115121

- 5115121

- Availability:

- FACTORY SHIPPED

- Shipping:

- Free Shipping

Description

BendPak 1302BA-302 Digital Automatic Tubing Bender with DeLuxe 302 Tooling Package / 60Hz 208-230V 1-Ph.

The BendPak 1302BA-302 is a powerful digital exhaust pipe bender designed to expedite any bending process and bring an extra level of precision to your workshop. Convenient space-saving, side-loading swager lets you load longer pipe, even when your back is against the wall. Includes the deluxe 302 die package and a dual-function, end-finishing unit for precision OE expansions and flares.

AUTOMATIC PIPE BENDER

Fully-Automatic Digital Pipe Bender The BendPak 1302BA series of pipe benders features an ergonomically placed and highly sophisticated keypad display that can record bending patterns for accurate and repetitive use. For extremely busy shops, an automatic pipe bender is a must-have item for anyone looking to save time and duplicate predictable results with ease.

NOTHING FASTER OR EASIER THAN AN AUTOMATIC PIPE BENDER

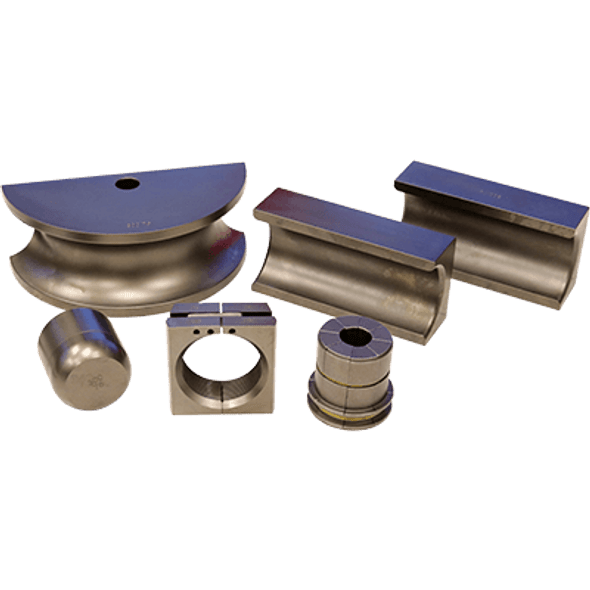

QUICK-CHANGE BENDING DIES

BendPak pipe benders feature twist-lock tooling and quick-change bending dies that are absolutely one of our most copied designs across the entire industry. We’re flattered, really, but if you want the best, most consistent bends, make sure you choose BendPak.

DIGITAL CONTROL

Hardcore users will appreciate the convenience of our digital control that gives you digital die angle readings right up front. An advanced, programmable mini-computer is safely enclosed within the front upright of the bender, allowing effortless fabrication on virtually every original equipment exhaust system. The program data control board manages all bending functions, automatic or manual, and stores up to 99 different bend depths.

180° BENDING CAPACITY

For maximum bending capability, go with a pipe bender from BendPak. Capable of bending 170° (or 180° with optional die), you can get a full U-shape with ease. We bend at a 5” radius: no pipe sticking, no hang-ups. Our pipe bender relief cut design is the best in the business and solely found at to BendPak. This design keeps each operation uniform throughout the entire cycle and prevents unwanted crimping or deformation.

3" BENDING CAPACITY WITH DIE KIT

Our 3” bending dies are proof of BendPak’s dedication to creating pipe benders of superior quality. They may look like most pipe benders on the market, but no one else uses our step-cut process for the die rails. Our large tubing is well-contained for more uniform bends. Not to mention, you can also expand and flare your tubing with equal ease and accuracy.

LONG-STROKE BENDING CYLINDER

An extra-long, 14” bending cylinder replaces pusher block extensions for small-radius die bending operations. The cylinder, as on all our pipe benders, can be retracted even further if you need more room to change dies or take out bent tubing.

CLAMPLESS SWAGER

A clampless swager comes standard on every pipe bender we make. 30,000 lbs. of force offer quick and precise end forming. Faster setups, more accurate bends—what more could you ask for? I.D. expansions, O.D. expansions, slip-fits, flares, ball-joints, reductions and manifold flanges are a cinch with BendPak tooling. To make things even easier, all of our pipe bender tooling is quick-release; you never see an outdated vise in the clamp assembly. Narrow-hinged collars simply drop into position and allow for flare tubing ends as close as 3". You’ll never worry about slippage, either, because the more pressure you put on the clamps, the tighter they grip.

INTERNAL SEGMENT EXPANDER

Our internal segment expander is just as unique as our clampless swager and can be used for I.D. expansions, O.D. expansions, slip-fits, flares, ball-joints and manifold flanges. The buttress canister has a single position setting for all I.D. expansions, but can also be adjusted for special sizing requirements. A single arbor is used for all tubing sizes 1.5" - 3". The clampless swager and internal expander make completing end-finishing operations with unparalleled ease: reducing, internal swaging, flares, flat flares, ball-joints, etc. The pipe bender is equipped with a double-ended cylinder for both the clampless swager and segment expander. A single control handle operates the cylinder and is placed toward the middle, letting operators stand comfortably in one location and still operate both sides.

ELECTRIC FOOT SWITCH

For added convenience and versatility, we’ve included an independent remote foot switch that lets you conduct manual bending operations while standing in front of the bending head or up to 4' away from the bender. This is especially useful when handling large tubing. Our pipe bender foot switches are industrial-grade and completely covered to keep you safe at all times during use.